|

10 Gallon Brew System

5 Gallon All-Grain

Brewing

Beer

Log

Brewing Tips & FAQ

Brewzilla System &

Mods

Build a Keg Washer

Concentrated Brewing

Exhaust Fan/Vent

Hood

Extract w/ Grains Brewing

Fermentation Fridge/Freezer

Fermzilla Conical

Hard Cider

Recipe

Hard Seltzer

(MikeClaw)

Monster Mill

Parti-Gyle Brewing

Saving

& Reusing Yeast

Sour & Funky Beers

Wine & Mead

Chest Freezer Kegerator

Fridge Kegerator

Sanyo Kegerator

Custom Tap

Handles

Keezer Compressor

Fix

Quick & Easy Drip Tray

Bread & Sourdough

Fermented Food

Gun Pictures

Hunting

Smoking Meat

|

|

Hard Seltzer (aka

MikeClaw) |

|

As much as I want to say I can drink super juicy NEIPAs &

barrel-aged stouts all day long, it's just not true. I used to have

a hard cider or something lighter after a couple more robust

beverages, but lately I've been trying more brands & flavors of hard

seltzer instead. What I really don't like is the $15 per

12-pack price tag, considering it's just sugar, yeast, and

flavoring. After doing a little research and trying a few

different batches, I think I have the process down. While my

seltzers may not have a perfectly clean fermentation profile, I can

knock out a 5-gallon batch for less than the cost of a 12-pack at

the store. I'll call that a win! I've listed out my process

for brewing MikeClaw below along with a few references and the

recipes I've brewed so far. It's a really quick & easy process and

turns out a crip & refreshing hard seltzer!

|

|

|

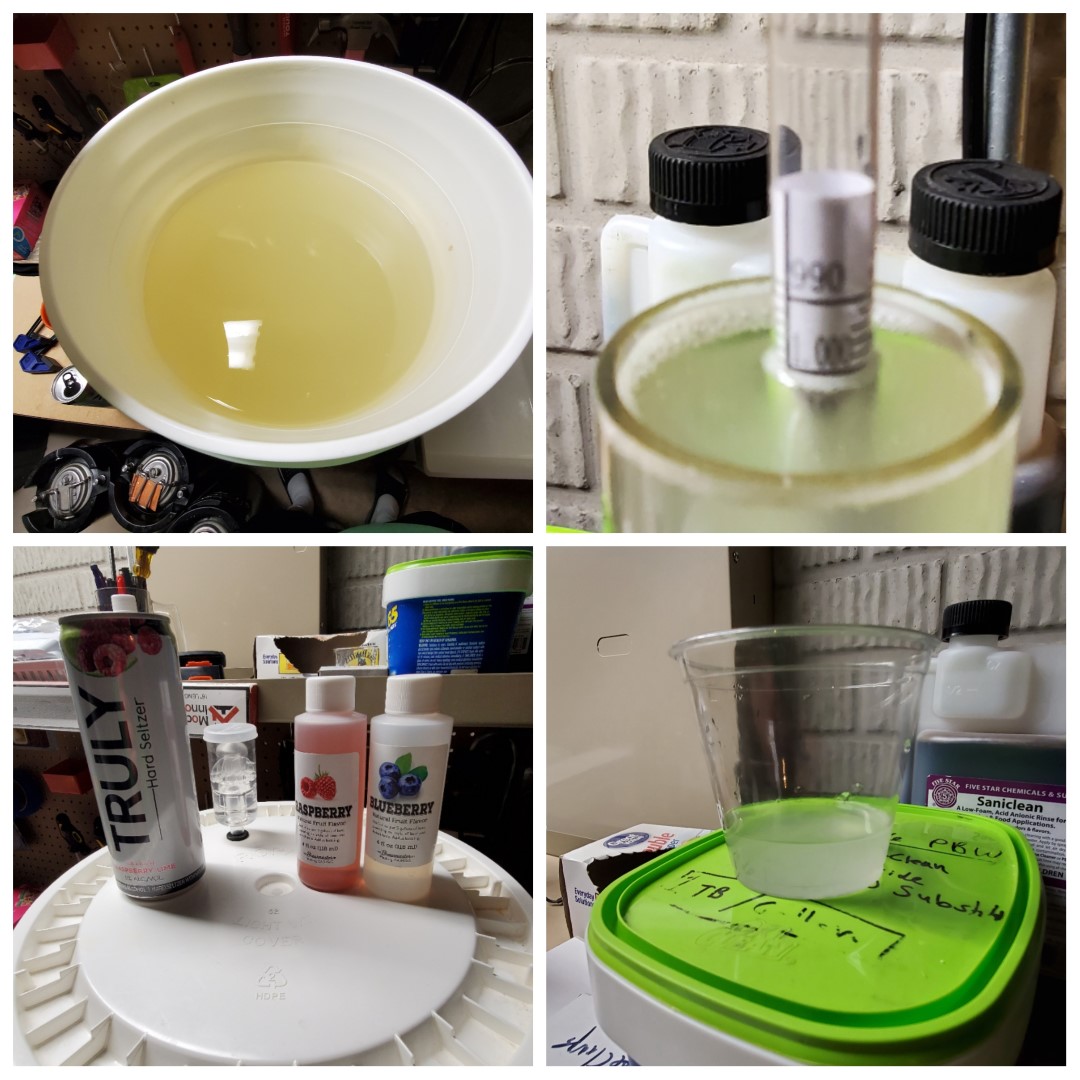

The brewing

process for hard seltzer is super quick and and easy.

I've listed my process below along with a few important

things to consider before brewing your first batch.

Water: There is quite a bit of discussion on

water for hard seltzer, mainly around the clarity of the

finished product. I use filtered tap water for my

seltzers, and I haven't had any issues with doing that.

If you choose to use RO or Distilled water, you may need to

add some brewing salts back in, depending on how much you

get into water chemistry.

Yeast Nutrient: Since you are only fermenting

sugar and water, the yeast will want/need a little help to

get going. I'm lazy, so I only add yeast nutrient &

energizer to the seltzer in the kettle. Others have had good luck with

staggered nutrient additions, which have really caught on in

the mead world over the last few years. That requires

buying different types of nutrients and adding them over the

course of a few days when fermentation is first starting

off. Both methods will result in a good seltzer, so do

some experimenting and see what works for you.

Flavoring: There are several different

flavoring options for hard seltzer. I've experimented

with the standard beer fruit flavorings (usually made by

Brewers Best (BB)) as well some

Amoretti Craft Puree, which adds a really fresh and

bright fruit flavor. Both have their benefits and

drawbacks. The BB flavorings are relatively

inexpensive, but some are better than others. I find

the Cherry to be very artificial tasting, and the Peach

tastes more like canned peaches rather than fresh. The

Amoretti has really great and fresh fruit flavor, but the

cost is around 4-5 times that of the BB option. I have

been experimenting with the BB flavors at kegging, and then

adding a splash of the Amoretti Craft Puree to each glass if

I think the batch needs more flavor. As I dial in what

BB extracts I like and in what volume and combination, I

will probably use less of the Amoretti, but it all depends

on what I'm looking for. I would suggest trying both

and seeing what your preference is, or go with a combination

as I have been doing.

Yeast: Yeast varieties for Seltzers have

changed as more and more brewers (home & professional) have

started experimenting with brewing seltzers. A lot of

people initially used wine yeast, but it appears the new

go-to yeast is the fast-fermenting Kveik yeast, specifically

the super neutral Lutra variant.

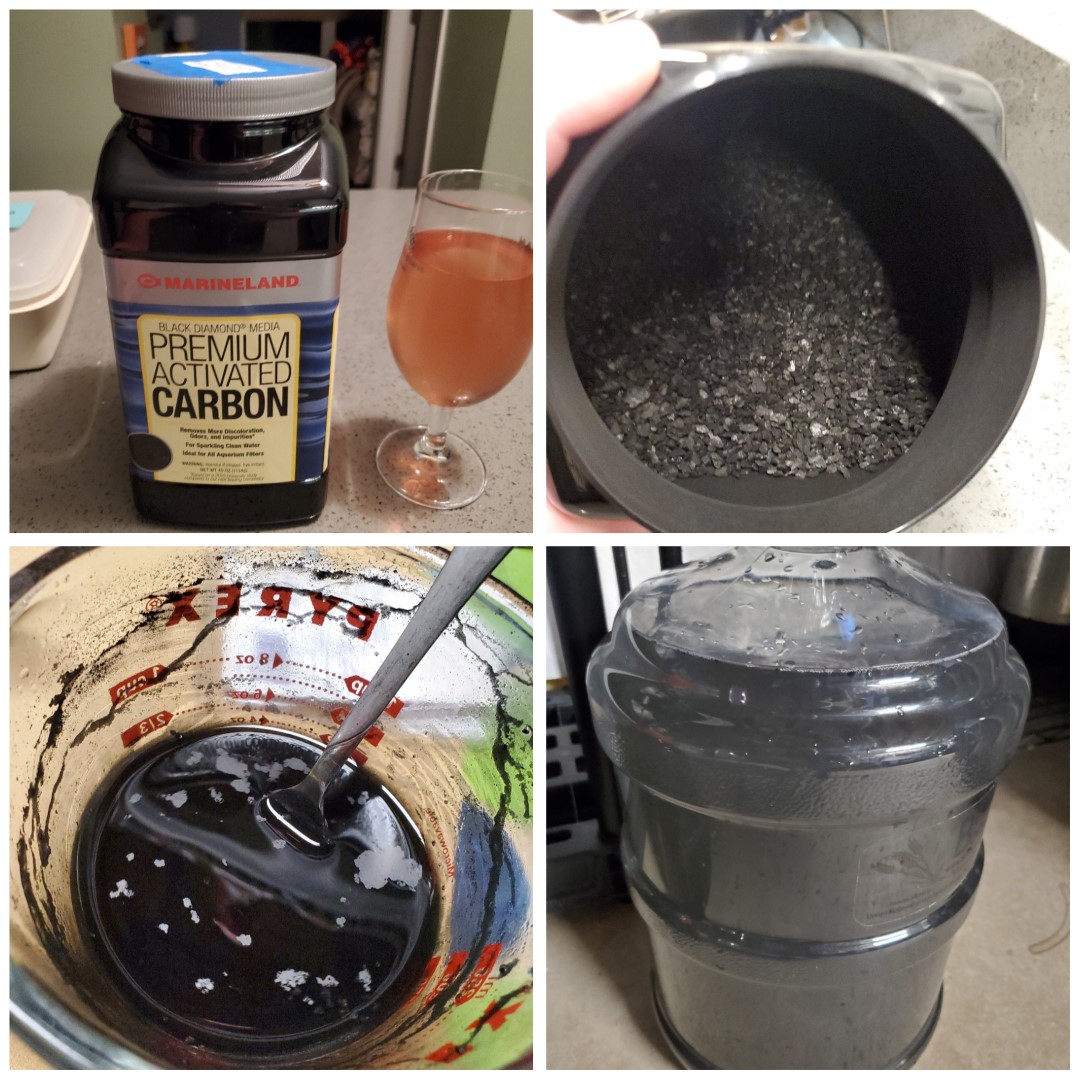

Clarity & Flavor Reduction - Activated Carbon &

Carbon Filtering

(NEW): Given time, the yeast will drop out of

suspension and you should be left with a crystal clear

seltzer. It took me a couple batches to figure out

that wine yeast flocculates (drops out) much slower than ale

yeast. I found it took at least 3 weeks to achieve clarity

without going through any other measures. That's why

some of my first batches were a bit cloudy, even though they

reached their final gravity. I also noticed a slight

fruity ester from the yeast that was always in the

background. After reading through an article in

Zymurgy magazine about brewing hard seltzer at home, I

noticed they recommended the use of activated carbon to help

strip additional yeast and fermentation character out of the

final seltzer. I've added a section to the site below

that goes through the process I followed in more detail in

case you want to try it on your seltzer at home. I was

VERY happy with the results!

|

|

|

|

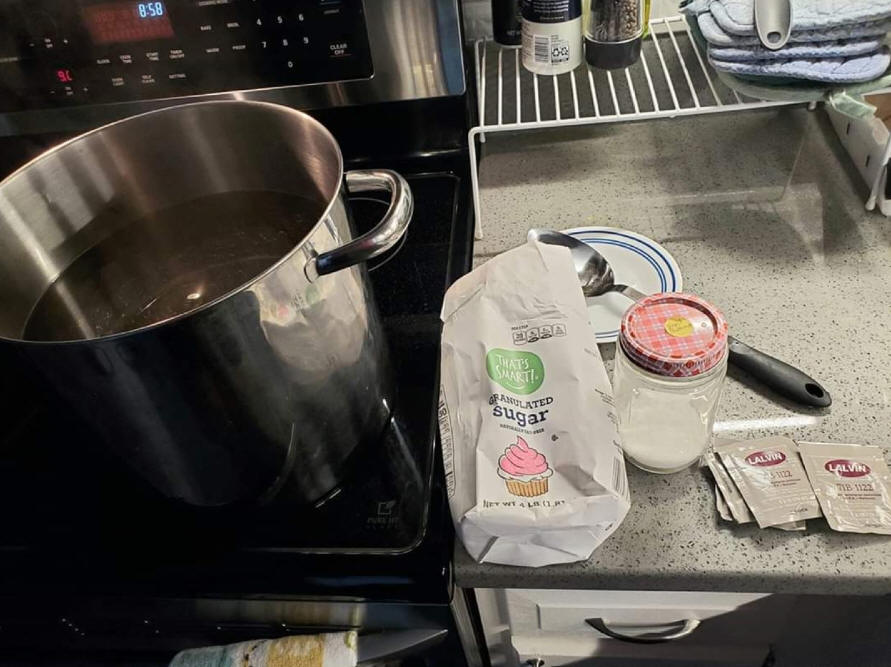

Ingredients:

-

4lb Table

Sugar

-

2 tsp Yeast

Nutrient

-

2 tsp Yeast

Energizer

-

1-2 packs

yeast (71-B, Kveik, or other neutral variety)

-

1-2 TB

Lemon Juice (optional)

Brewing

Process:

-

Bring 1-2

gallons of water to a boil along with the 4lbs of table

sugar. Make sure to stir the pot frequently until

the sugar is totally dissolved. Alternatively, you

could bring just the water to a boil and add the sugar

off heat, stir to mix, and add it back to the heat.

-

Boil for 5

minutes and turn off the heat.

-

Add Yeast

Energizer & Yeast Nutrient (and lemon juice if you're using) and

stir to combine.

-

Chill in a

water bath or other chilling method until the temp is

around 80-85 degrees.

-

Add the

chilled sugar water to your sanitized fermenter and top

up to 5 gallons with cold filtered tap water or RO/Distilled.

-

Sprinkle on

yeast, mix and aerate (I use a mix-n-stir), attach lid & airlock, and wait.

Fermentation seems to take a little longer with wine

yeast, so give it a couple weeks before taking a gravity

reading.

-

Aerate &

degas once or twice a day for the first 3 days or so.

This helps speed up the fermentation and reduce some of

the perceived yeast aromas I was noticing

post-fermentation.

Kegging:

This is where I

will add the Brewers Best (or other) flavoring to the keg and rack the

seltzer on top of the flavoring to mix. I've found

that 4-6 oz of BB extract is about right for me, depending

on the flavor(s) being used. This is where you can

experiment with blending different flavors, brands, and amounts to

see what works best for you. I would start with less

flavoring than you think, then rack the seltzer onto the

flavor, and try it again before you're done. For

carbonation, I just use the standard process, pressure, and

temp as with my beer. I find that the carbonation

isn't quite as high as commercial brands, but that's not

necessarily a bad thing, since those tend to make me burp a

ton. If you have a dual-pressure regulator, you can

try a higher pressure to see what you prefer.

|

|

|

|

|

|

Activated Carbon

- My first few batches of seltzer were a bit

cloudy, and they definitely had some residual

fruity and slight sulfur flavors & aromas.

The fruit flavoring additions did a good job of

masking these flavors, but I wanted to work on

trying to get rid of them before kegging.

My first attempt to improve clarity was to use

Activated Carbon in the secondary fermenter

based on some initial online searching.

This worked pretty well, but some of the

fermentation character was still coming through

in the final seltzer. Here's the process I

follow to add Active Carbon to my seltzers:

1. Clean &

sanitize a secondary fermenter

2. Add

1-2 TB of Active Carbon (AC) to the bottom of the fermenter

3. Rack

seltzer on top of AC to mix

4. Allow

the seltzer to sit for a week or two before proceeding to

carbon filtering (below) or kegging

|

|

|

|

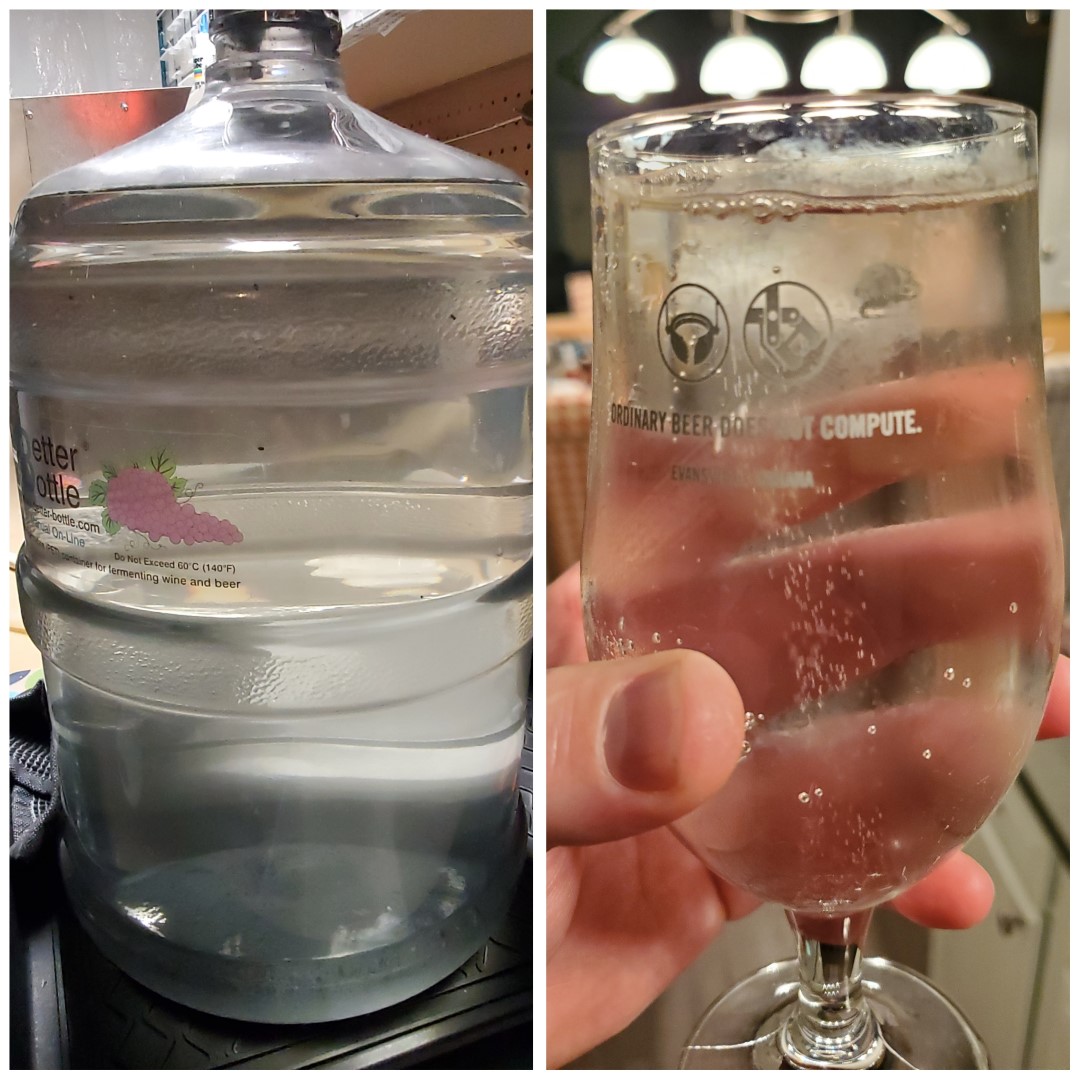

Carbon Filtering - With some residual

fermentation character still coming through

after trying to use Active Carbon in secondary, I

decided to try pushing my finished seltzer

through a whole-house carbon filter by jumping

from one keg to another, and that was a game

changer! After filtration, the seltzer was

almost as neutral as water, with all those

fermentation characters completely removed.

I likely don't need to use the activated carbon

in secondary, but it isn't doing any harm, so

I'm going to keep using that along with carbon

filtering to achieve a very neutral finished

product. Since this process requires

prepping and sanitizing more equipment, I usually like to

filter more than one batch of seltzer at one time if

possible. Here's the process I follow for carbon

filtering my seltzers before flavoring in the keg:

1.

Clean and sanitize a keg for the pre-filtered seltzer and

however many kegs you plan to keg as well

2.

Rack seltzer over to pre-filtration keg, attach lid, add CO2

& vent headspace

3.

Attach filter with quick disconnects to the pre-filtered keg

and the post-filtered keg, and make sure the direction of

flow on your filter is going the correct way

4.

Open the post-filtered keg pressure release valve to allow

the keg to be filled with the filtered seltzer

5.

Apply 5-10 PSI of CO2 to the pre-filtered keg and monitor

the flow through the carbon filter. You want around 1

gallon or less of seltzer to be passing through the filter

every minute.

6.

Repeat with second keg, or disconnect equipment and

thoroually clean the filter housing, filter, and tubing

|

|

|

|

Recipes:

Here are a few links to the Hard Seltzers I've made so far.

I'll keep adding more as I go along on my

Brew Log

page, so check that out for updated recipes, processes, and

ideas.

Future

Seltzer Ideas:

-

Double

Batch & Dilute: After talking with some pro

brewers and fellow homebrewers that are making Hard

Seltzer, they seem to be brewing higher gravity/double

batches of seltzer and then diluting them with water

post-fermentation. I like this idea for a couple

reasons. First being that you can brew two (or

more) batches of seltzer using only one fermenter, as

well as the time savings. The second would be

potentially reducing the amount of esters that I've

noticed after fermentation completes. If I brew a double

batch and then dilute with water, I would assume the

overall yeast character should be diluted as well and

result in a more clean tasting alcohol base for the

fruit. I'll be giving this a try on my next batch

to see how it comes out. As part of that

experiment, I will also be using tap water to dilute one

half, and distilled on the other to see if I notice any

differences.

-

Different Fruit Flavorings: A few of our

homebrew club members have tried what appear to be

vaping flavorings on both their beers and seltzers, and

have had good luck with the

Wizard Labs brand. One thing they all

mentioned is that these flavorings are VERY

CONCENTRATED, and only require a few drops for a whole

5-gallon batch. This kind of scares me a bit, but

I may need to order a few and try them out. The

prices seems very reasonable for how much flavor they're

supposed to add.

-

Vodka

"Seltzer" - Several companies have started releasing

vodka-based "seltzers" or ready-mix beverages.

This takes the brewing aspect out of things, but it

would still be interesting to play around with. If

you can get some cheap vodka from Sam's Club or Costco,

it may be worth a try, but it would definitely be more

expensive than just fermenting sugar. Brulosophy

did a great write-up on the process for making a vodka

seltzer

HERE.

|

|

|

|

Amoretti Craft Puree - Use to flavor the seltzer per glass

or the whole batch:

Amoretti

|

|

Contact Information:

MikeYoungHB

at gmail.com

*As an Amazon Associate I earn from qualified purchases*

|

|